Project background

Henan Biyang county is an important metal and non-metallic mineral base in southern Henan province, with more than 100 million tons of limestone reserves. Henan Biyang customer invests the limestone grinding powder production line and the fineness is 325mesh. It is mainly used for desulfuration in power plant. The process of desulfuration in powder plant is mostly flue gas desulfurization, which is the most effective and widely used technology for controlling SO2 gas emission in coal-fired power plants. In the method of flue gas desulfurization, the limestone-gypsum wet flue gas desulfurization is the most mature and most widely used desulfurization technology in the world, and its desulfurization efficiency is above 95%.

Project details

Raw material: limestone

Output size: 325mesh

Capacity: About 30 t/h

Application : Desulfuration

Main equipment: YGM190 high pressure suspension grinder

Project location: Biyang county, Zhumadian city, Henan province

Outstanding advantage

The grinding device of YGM190 high pressure grinder of Tongyong Machinery adopts overlapping unique design. In the grinding chamber of main engine, 1500kg—2000kg of pressure device is designed on the top of plum flower shelf. The output increases by 10% to 30% under the same powder. It adopts multi-stage seal with good sealing performance. The replacement cycle of grinding roller and grinding ring is long and maintenance cost is low. The noise is low, and the dusting effect completely meets the national emission standard.

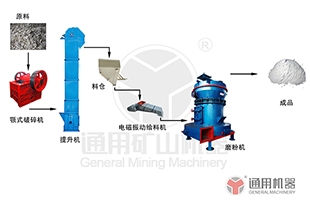

Technical process

The large limestone is crushed into the feeding size(15mm-50mm)which can enter the grinder by crusher. After crushing , small limestone is sent to stock bin by elevator and is sent into grinding chamber of the grinder uniformly and quantitatively by vibrating feeder for grinding. After grinding, the material is graded by powder concentrator. The unqualified powder will return to main engine to regrind after grading. The powder which meet the fineness requirement will enter dust collector via pipeline with airflow for separation and collection. The finished powders collected are sent to finished product warehouse by delivery device via discharge hole. Then they are packed by powder tank car or automatic packing machine uniformly.

Customer feedback

General machinery runs smoothly. The product fineness and capacity can meet the requirements. And the powder consumption is little. The most important is that the power plant is very satisfied with our desulfurizer. We become high quality supplier of the power plant. Thanks to General Machinery.