-

- Industrial Grinding

-

Project DackgroundBauxite is a kind of high quality fireproof material, it can also be used for aluminum smelting, and i... MORE>>

- Aggregate

-

Project BackgroundIn Decmeber, 2016, we made a 200 t/h basalt crushing production line for a customer in India. The out... MORE>>

- Metallic Mineral

-

Project BackgroundThe process of copper beneficiation line is relatively simple. Raw materials are crushed before the gr... MORE>>

- Building Materials

-

Project BackgroundRiver pebble is a natural stone taken from tore which is formed by uplifted ancient river bed through ... MORE>>

-

- Industrial Grinding

-

In industrial grinding filed, General Mining Machinery grasps professional technologies throughout the entire process ch... MORE>>

- Aggregate

-

In aggregate filed, General Mining Machinery with professional crushing technologies for soft, medium hard and hard mate... MORE>>

- Metallic Mineral

-

In metallic mineral filed, General Mining Machinery can process soft, medium hard and hard minerals and provide various ... MORE>>

- Building Materials

-

In building material field, General Mining Machinery provides clients with professional resolution and complementary pro... MORE>>

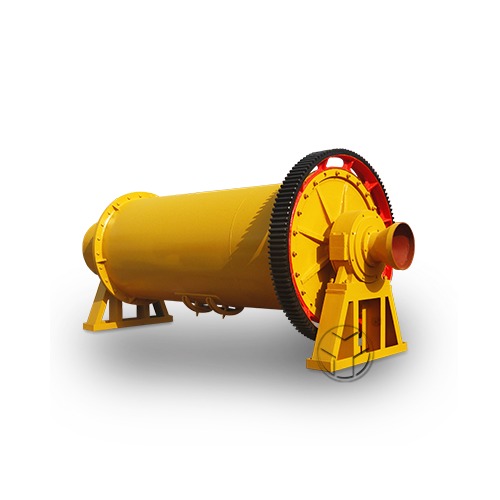

Ball Mill

【Feed Size】 < 25mm

【Finished Product Size】 20~200目

【Capacity】 0.65~90t/h

The ball mill is one of our classic machines. The new type ball mill has advantages over final product fineness, driving force saving and power grinding efficient and creates more benefit for customers. So it has been widely used in beneficiation, building material and chemistry industries.

The ball mill is applied to grind and process chalk, gypsum, brick, etc.

- Features

- Pictures&Videos

- Specifications

- Applications

- Cases

- Download

|

|

The main shaft adopts large diameter double row self-aligning roller bearing to replace sliding bearing, which reduces fabrication and energy consumption and makes the mill easy startup.

The feeder,with simple structure and separate installation, has two types, union feeder and drum feeder, and the mill also remains cover structure of common mills and has large diameter inlet and outlet bringing about large capacity.

With no inertial impact, the ball mill runs steadily and needs less time for maintenance, which improves efficiency. |

|

The ball mill is one of our classic machines and it is designed and developed based on traditional ball mill in accordance with several-year market survey and customer feedback. Under same conditions, the new type ball machine has advantage over final product fineness, driving force saving and power grinding efficient and creates more benefit for customers. And it applies to grind various ores and other materials and has been widely used in beneficiation, building material and chemistry industries, such as processing silicate product, new building material, cement, refractory material, fertilizer, glass and china and black and non-ferrous metal ore beneficiation etc. The ball mill is applied to grind and process chalk, gypsum, brick, limestone, feldspar, silica, quartz, ceramics, clay, glass, rubber, plastics, non-ferrous metals and ferrous metals, etc. |

|

![]() Structural Characteristics

Structural Characteristics

Ball mill belongs to mineral crushers as well as preparation equipments. It is a key machine for further crushing after materials being crushed. Ball mill has two grinding methods, dry grinding and wet grinding, and it is divided into grid type and overflow type according to discharging methods.

The ball mill is composed of feeding device, discharge device, rotation device and drive device (including speed reducer, small drive gear, motor, electric control cabinet). And the trunnion spiral is steel casting with removable lining; large rotary gear adopts casting gear hobbing processing; there are wearable linings in the barrel thus it has good abrasion resistance. In one word, the ball mill works steadily and reliably.

Internal mill structure covers the lining plate, grate plate, partition panel, feeding and discharging devices. The lining plate is for protecting the barrel from direct impact and friction by grinding medium and materials and different types of lining plates can adjust the moving status of the grinding medium.

![]() Working Principles

Working Principles

The ball mill is a horizontal type and tubular running device which has two warehouses. This machine is grid type and its outside runs along gear. Materials uniformly through feeding trunnion spiral enter into the first hopper where has stepped lining plates or corrugated lining plates and various specification steel balls; when the cylinder rotating, the steel balls are lifted by centrifugal force and then fall by gravity, which brings impact and grinding to the materials. After coarse grinding in the first hopper, the materials through monolayer partition panel enter into the second hopper which has plane scale board with steel ball inside to be ground again. Fianlly, ground materials come out through the discharge grate and the grinding is completed.

|

|

|

|

|

|

|

|

| Model | Shell rotation speed(r/min) | Ball load | Feeding size | Discharging size(mm) | Capacity(t/h) | Motor power(kw) | Weight |

| Ф900×1800 | 36-38 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 18.5 | 4.6 |

| Ф900×3000 | 36 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 | 5.6 |

| Ф1200×2400 | 36 | 3 | ≤25 | 0.075-0.6 | 1.5-4.8 | 30 | 12 |

| Ф1200×3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

| Ф1200×4500 | 32.4 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

| Ф1500×3000 | 29.7 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 | 15.6 |

| Ф1500×4500 | 27 | 11 | ≤25 | 0.074-0.4 | 3-6 | 90 | 21 |

| Ф1500×5700 | 28 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 | 24.7 |

| Ф1830×3000 | 25.4 | 11 | ≤25 | 0.074-0.4 | 4-10 | 130 | 28 |

| Ф1830×4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 4.5-12 | 155 | 32 |

| Ф1830×6400 | 24.1 | 21 | ≤25 | 0.074-0.4 | 6.5-15 | 210 | 34 |

| Ф1830×7000 | 24.1 | 23 | ≤25 | 0.074-0.4 | 7.5-17 | 245 | 36 |

| Ф2100×3000 | 23.7 | 15 | ≤25 | 0.074-0.4 | 6.5-36 | 210 | 34 |

| Ф2100×4500 | 23.7 | 24 | ≤25 | 0.074-0.4 | 8-43 | 245 | 42 |

| Ф2100×7000 | 23.7 | 26 | ≤25 | 0.074-0.4 | 8-48 | 280 | 50 |

| Ф2200×4500 | 21.5 | 27 | ≤25 | 0.074-0.4 | 9-45 | 280 | 48.5 |

| Ф2200×6500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 14-26 | 370 | 52.8 |

| Ф2200×7000 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 | 54 |

| Ф2200×7500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 | 56 |

| Ф2400×4500 | 21 | 30 | ≤25 | 0.074-0.4 | 8.5-60 | 320 | 65 |

| Ф2700×4000 | 20.7 | 40 | ≤25 | 0.074-0.4 | 12-80 | 400 | 94 |

| Ф2700×4500 | 20.7 | 48 | ≤25 | 0.074-0.4 | 12-90 | 430 | 102 |

| Ф3200×4500 | 18 | 65 | ≤25 | 0.074-0.4 | according to the technological conditions | 800 | 137 |

The ball mill is applied to grind and process chalk, gypsum, brick, limestone, feldspar, silica, quartz, ceramics, clay, glass, rubber, plastics, non-ferrous metals and ferrous metals, etc.

|

|

|

|

|

|

| Limestone | Quartzite | Cretaceous | Feldspar | Loam |

|

|

|

|

|

|

| Barytes | Cobblestone | Dolomite | Dolomite |

Molybdenum Ores |

|

|

|

|

| Afghanistan Copper Beneficiation Production Line | Liaoning Iron Ore Benificiation Production Line | Hunan 20 TPH quartz sand powder grinding production line |

Almost 15 years service experience and thousands of user’s requirement make General Mining Machinery

know well about your concern and requirement and offer you more specific resolution.

Cellphone

Cellphone

WeChat

WeChat

Double bearing and low energy consumption

Double bearing and low energy consumption